————–

Note: This is the fourth in a series of articles here at Forgotten Fiberglass that showcase a story called “The Glassmakers 1960” published in Sportscar Graphic in May-June 1960. In this 1960 article, Almquist, Devin, Kellison, LaDawri, and Victress were showcased. We have separated the full article into “five” more readable stories – one for each of the car marques discussed.

Click here to review all articles published in this series.

————–

Hi Gang…

If only we had an article in 1960 that told us what fiberglass companies were in business and going strong…..

Wait! We do! This 12 page tome appeared in Sportscar Graphic in June 1960 and included two pages or more on each of the following cars: Devin, Kellison, LaDawri, Victress, and Almquist. And those were the “Big Fiber Guns” of fiberglass

then, and it’s a very respectful review of each of these companies and what they had to offer.

I’m going to break this up into 5 separate articles with each one focusing on a specific fiberglass sports car company from this article. Today’s story, the fourth in the series, will focus on the sports cars built by Victress Manufacturing.

So sit back, grab a coffee, turn on some music, and let the fibers fly free…

Off we go gang!

————–

The Glassmakers…1960: Victress Manufacturing

Sportscar Graphic, May-June 1960

By Bob Rolofson

Photos by Rolofson, Bob D’Olivo and the Inman Co.

Want A Sportscar? Have Budget Problems? These Fiberglass Companies Have Economy-Minded Answers That Range From Bodies Fresh From The Mold To Completed Cars Ready For The Street Or Race Course

Victress Manufacturing:

The Victress Manufacturing Company, 11823 Sherman Way, No. Hollywood, Calif., has been in the fiberglass business since the beginning.

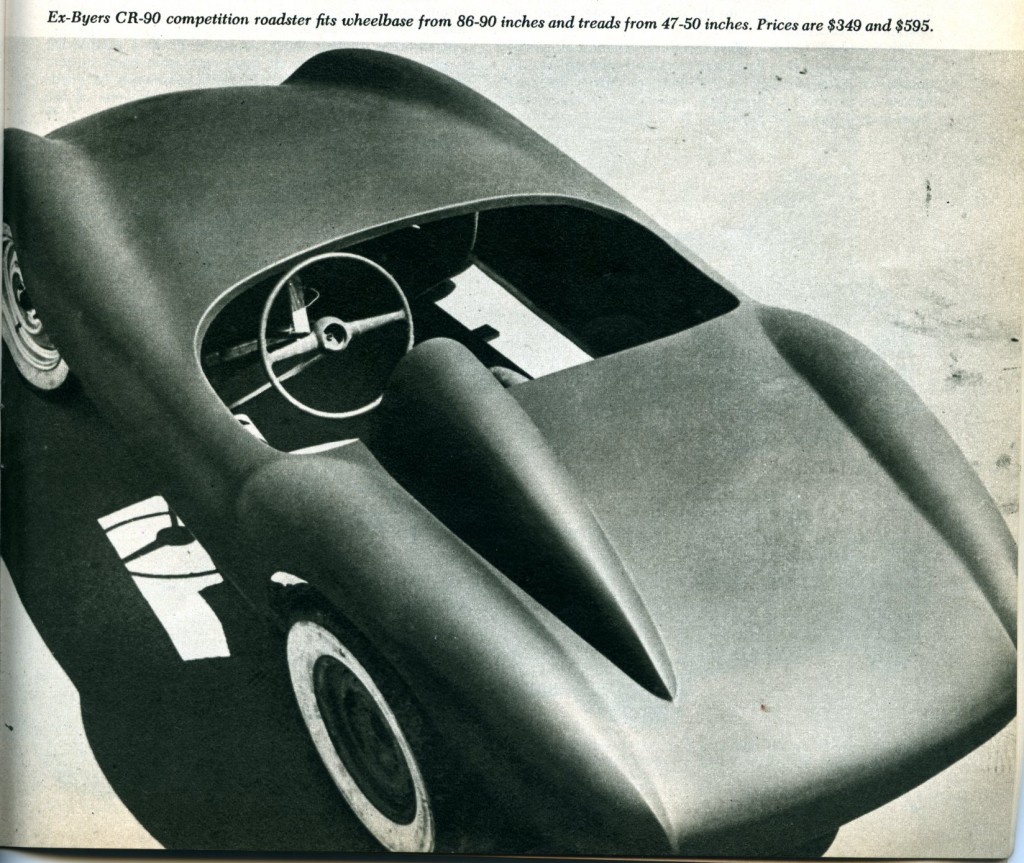

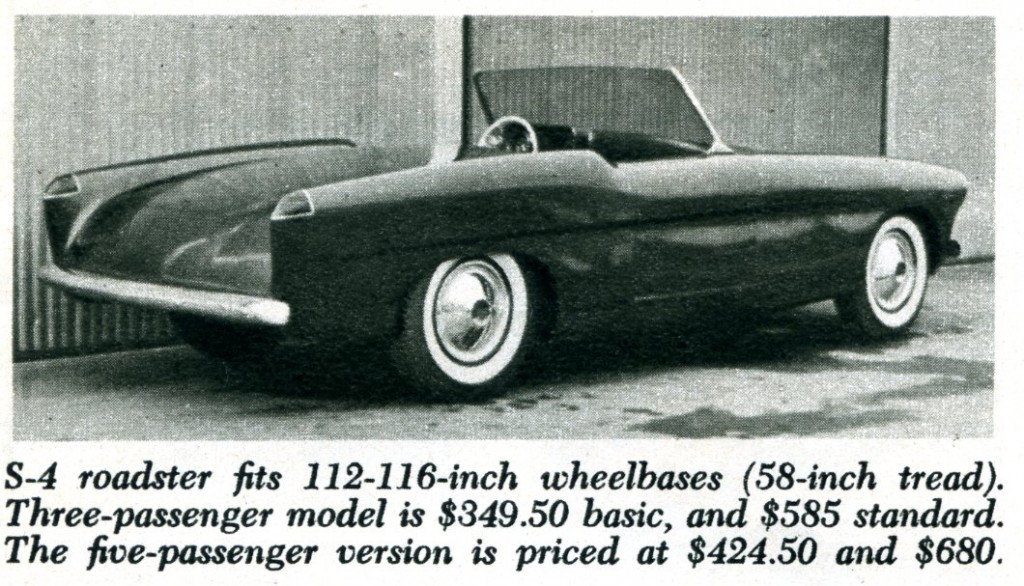

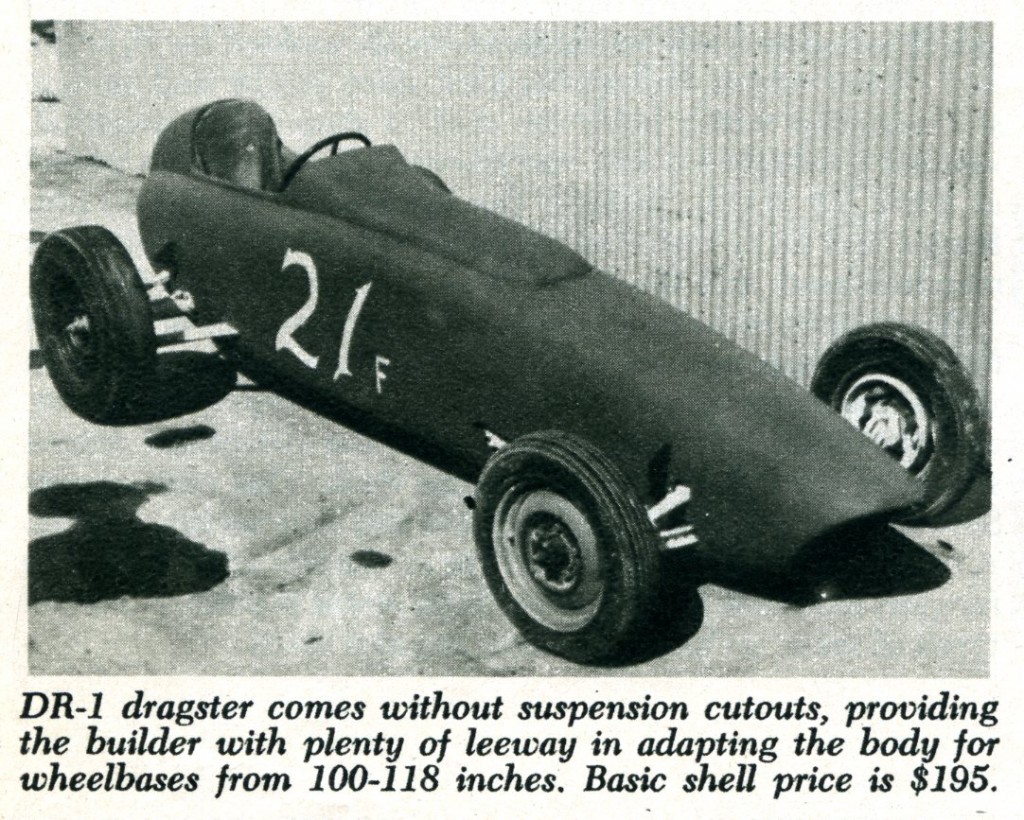

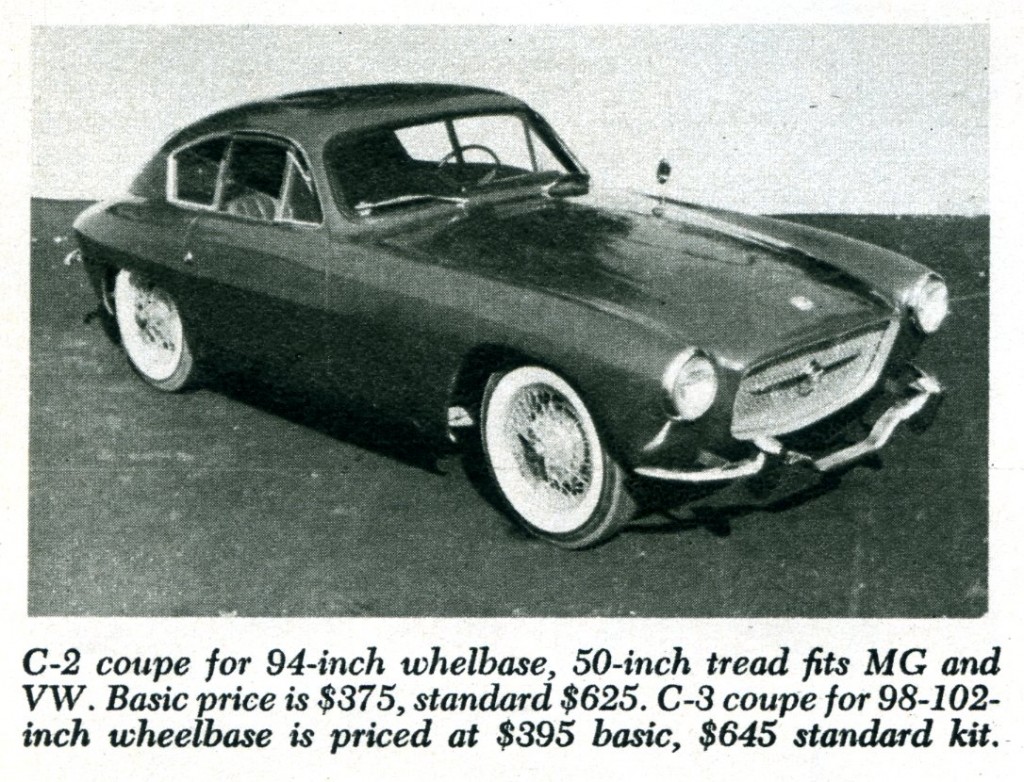

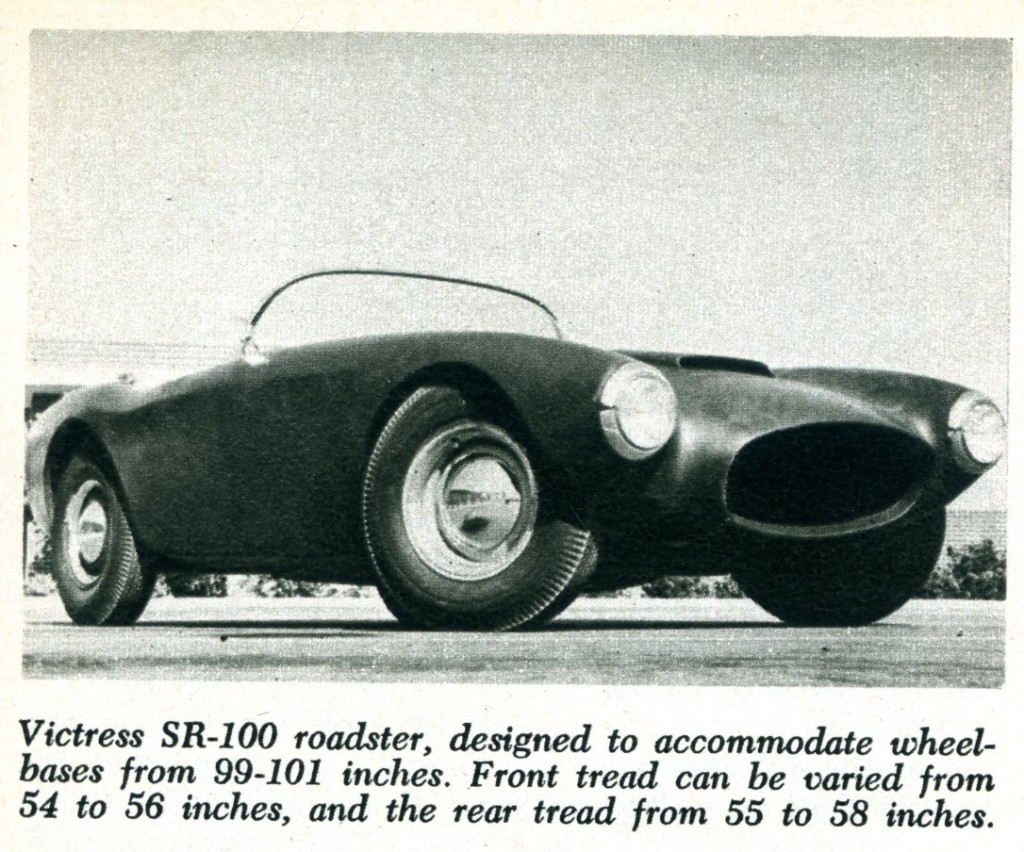

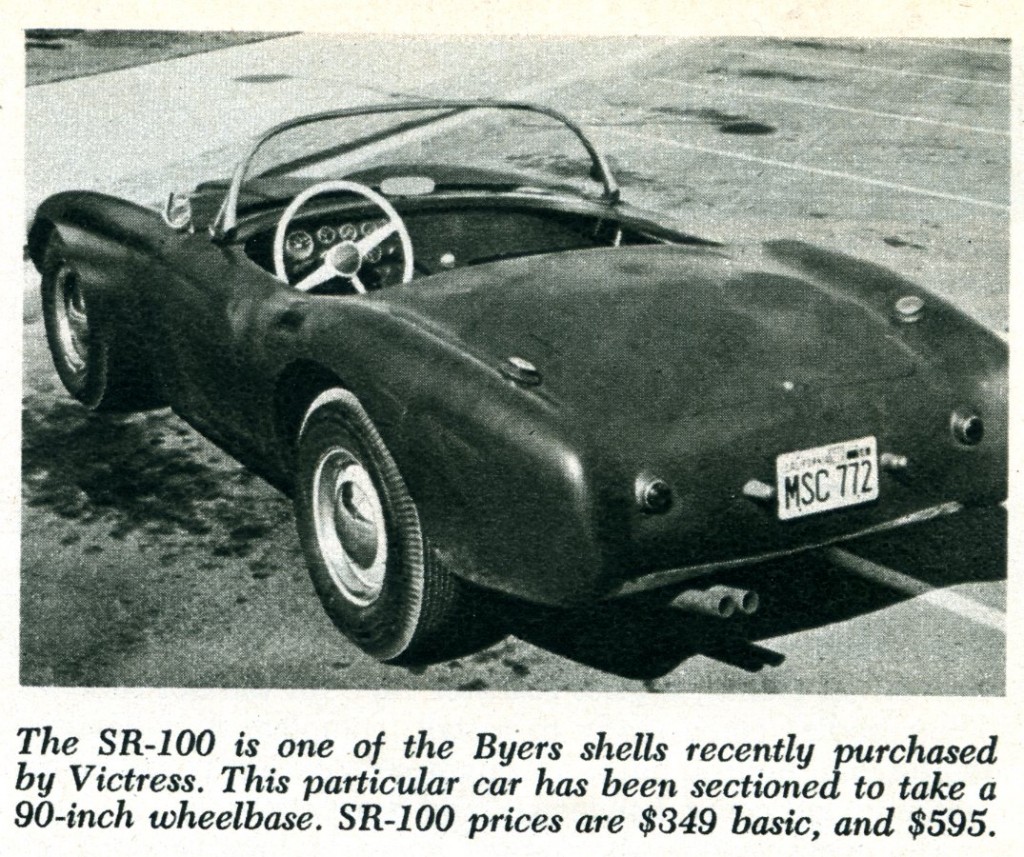

Although the vast majority of their work is devoted to government contracts, they still have the largest assortment of glass car bodies of any manufacturer. In addition to their line of two coupes, three roadsters and a dragster shell, they recently bought Jim Byer’s two sleek roadster molds, and are almost ready with a T-roadster for hot rods!

Victress have broken their sales and price list into two versions of each of their eight shells:

- A basic body, consisting of a completely formed shell trimmed on all edges

- And a standard kit, consisting of the trimmed shell with molded drain gutters on hood and deck, box section reinforcement on hood, deck and doors, hinges and latches installed and working on hood, deck and doors, cast aluminum windshield posts, a template kit for cutting wheel wells, firewall, floor kit for cutting wheel wells, firewall, floor boards, backrest, window lift mounts (coupes only), and resin and fiberglass supplies enough to make 40 square feet of fiberglass laminate.

As with all of today’s glass body builders, Victress have developed the finish and structural planning of their product to help the special builder both in the planning and building stages.

They go one step further than most, however, by keeping a constant check on each mold on a giant designer’s bridge which takes up one building at their plant. With this bridge they can control form shapes to .060-inch which boils down to a finished tolerance of from 1/8- to 3/16-inch on each shell!

Thoughts On The Article:

A few points here to consider gang…

First, it’s great to see that Victress was being recognized as being the largest assortment of glass car bodies of any manufacturer as of the date of this magazine – 1960. And I’ve always maintained this was true. Think of all the body styles they had – and nearly every one was available in two sizes. When you contrast that with other body manufacturers of the early to mid ‘50s, Victress accomplishments were impressive!

Second, times were tough in the fiberglass industry and the companies were being challenged on a variety of fronts. A recession in the late ‘50s made things far more competitive. More companies with new bodies – the big ones mentioned in this article – put pressure on Victress. Not to mention that other fiberglass companies were taking on government work as well – cutting into the contracts Victress had.

It was not “business as usual” and Doc Boyce-Smith and Merrill Powell would sell Victress Manufacturing to Les and Joan Dawes the next year – 1961.

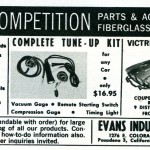

Finally, the point in this article that Victress bought out Byers was simply not true. I’ll let Merrill Powell confirm this with a response to this story, but I think I know how that rumor got started. Checkout the following advertising from Evans Industries that appeared in this same magazine issue:

Art Evans was making a big splash advertising Victress and Byers bodies in a catalog he distributed. While I’ve been able to find sales flyers from Evans Industries showing the different bodies, I’ve never found the catalog – until recently.

I’m pleased to say that Alden Jewell has located a copy and in the near future, we hope to have copies of this catalog and what it shows for sale. Should be fun gang!

For this first time since Hellings became a distributor for Victress bodies, Victress took on another distributor: Art Evans and Evans Industries. When I talked to Art about his memories of this time, he confirmed that they pushed the sales on these bodies hard, but soon backed off and closed the company. This meant that in the last year of Victress business, they lost their newly found distributor as well.

So…the last big “flash-bang” for Victress must have caused enough of a spark for magazines to take notice, but what they noticed wasn’t accurate. Victress hadn’t bought Byers. Both companies were viable and separate at the time. Instead, they made the mistake of thinking both companies had merged or one had bought the other.

Neither assumption was accurate. Victress went on to be sold intact to La Dawri in 1961, and Byers continued selling car bodies and then expanding into boats for nearly another decade.

Summary:

I’ll let Merrill Powell from Victress share his thoughts in the comments below, and look forward to sharing some of Evans Industries sales flyers and catalogs in future stories here at Forgotten Fiberglass.

Hope you enjoyed the story, and until next time…

Glass on gang…

Geoff

——————————————————————-

Click on the Images Below to View Larger Pictures

——————————————————————-

Thanks for the nice comment, Mel.

Geoff has it all right, about the misconception that we bought the Byers molds. I’m surprised Bob Rolofson made that mistake; he obviously didn’t check with us, Byers, or Art Evans before writing. The statement about the designer’s bridge was interesting; we did use one, made from garage door tracks, and hung from the rafters, in constructing the clay plug for the S-4. We had no end of problems with it , because the metal building moved with the sun, and so did the bridge! We destroyed it after we took the S-4 molds. For the C-2 and C-3 we used a floor-mounted bridge.

Strangely, the article doesn’t mention the S-1A or S-5. Perhaps Rolofson thought the designs were out-dated (which was probably true), and that the “newly-acquired” Byers designs were more current.

My all time favorite Victress would be the C-3.It looks great even today,great design has a way of being imeless..

MLK

~ SR100 & C2 are much more attractive than any thing from big 3. ‘easy on the eyes’ we once said. precede & predict auto styling around the planet for decades. elements of their design appear in cars today. bravo.

thirty plus years ago I saw a c2 coupe for sale with an early t-bird frame and running gear , at the Stafford Speedway swapmeet in Ct. wonder where it is now?

All incredible looking cars, but the 94″ wheelbase C2 really works for me… There is more good going on there than words can describe…