Hi Gang…

Haven’t we all been to “mecca” as children and driven sports cars before the age of nine?

Opps…I mean haven’t we all been to “Disneyland” and driven “Autopia” cars during our childhood, young adulthood, or later? If this fits you to a “T” then….you’ve been a fan of fiberglass for more years than you might have guessed – for the first cars that paced the track when Disney opened in July ’55 were:

- designed by Bob Gurr

- had their fiberglass bodies built by Glasspar

- and were assembled by the guys at Mameco

All legends of fiberglass sports cars of the 50s and beyond.

Our love for fiber history of the hasn’t been in vain. In fact, if you think about it, the public has known about the Autopia cars by Disney since they were originally built. It’s just that except for the few dedicated researchers and fans of Disney lore, the history of how these cars came to be has largely been “forgotten.”

Thankfully we can retell the story of these cars from a variety of sources. In the past few years, I’ve been fortunate to interview the following folks involved with this project:

- Bill Tritt from Glasspar who built the bodies

- Ed Martindale from Mameco who built the cars along with his partner Ted Mangels

- Bob Gurr who designed the car

And today, we have a great article which stitches together all of these folks and adds more detail. So, for you fiber fans out there, let’s see what Rod & Custom Magazine had to say about Disney’s Autopia ride in November ’55 – just 5 months after Disney opened in July of the same year.

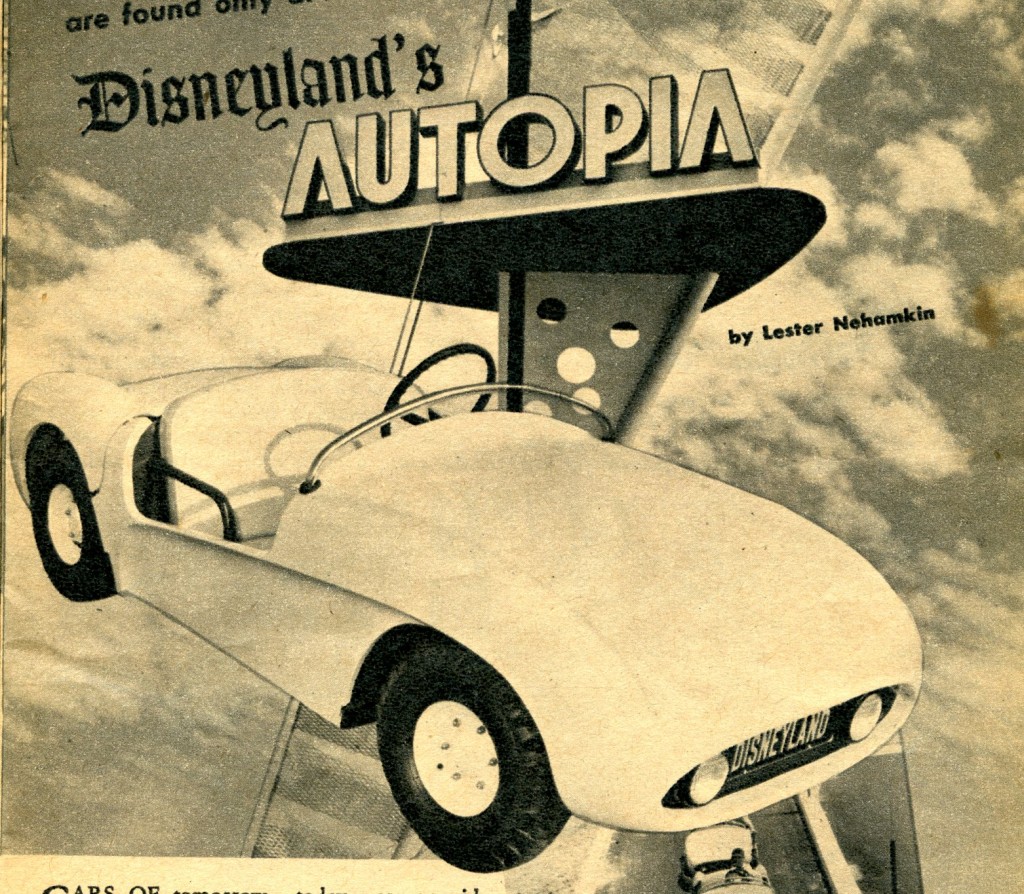

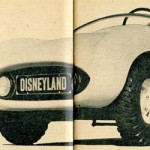

Disneyland’s Autopia

Rod & Custom, November 1955

By Lester Nehamkin

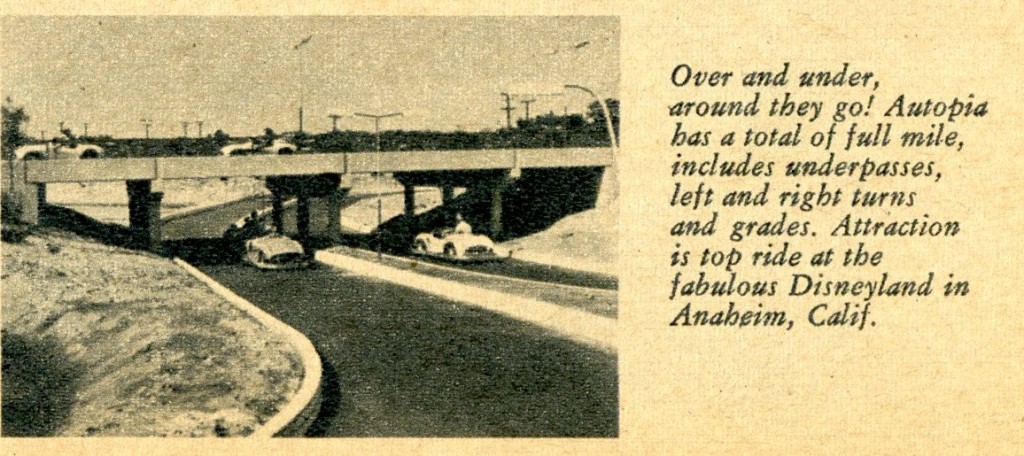

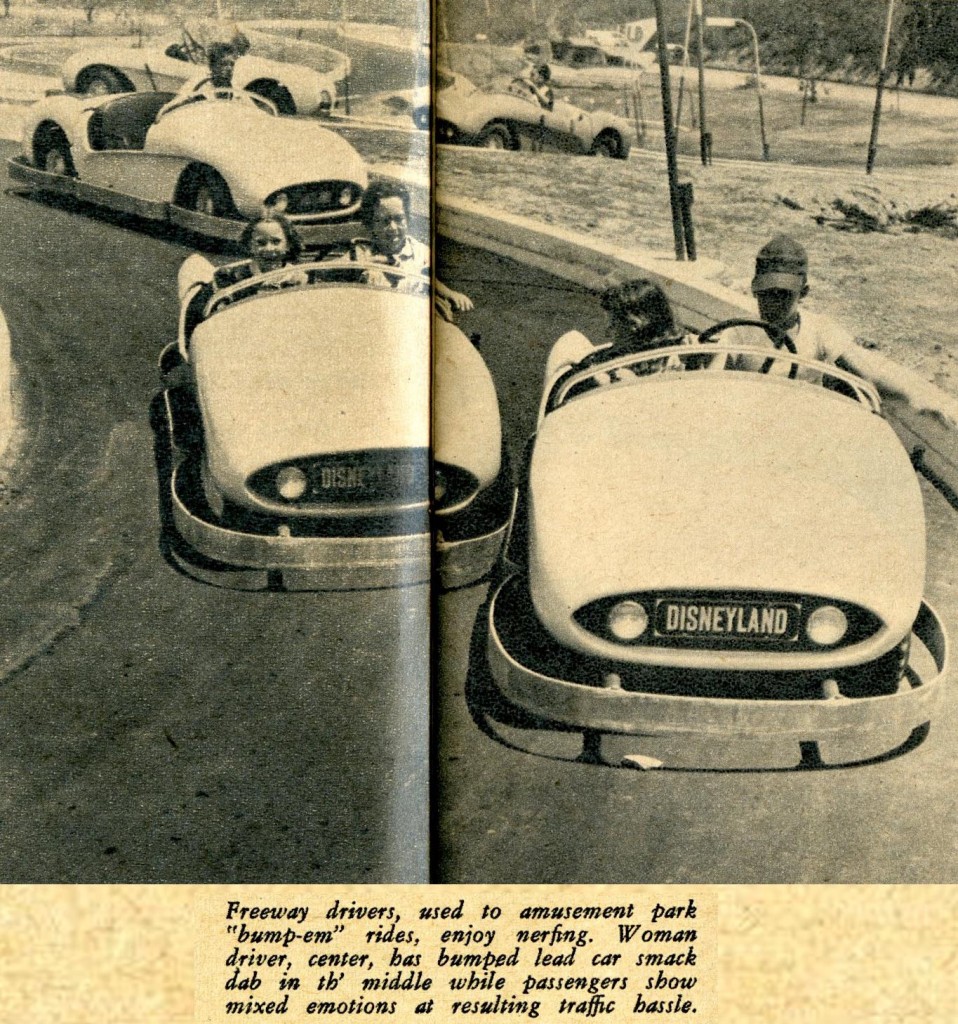

Cars of tomorrow–today–are providing thrills galore to young and old alike on the fabulous mile long, miniature freeway system Walt Disney has created, the Autopia section of Disneyland at Anaheim, California.

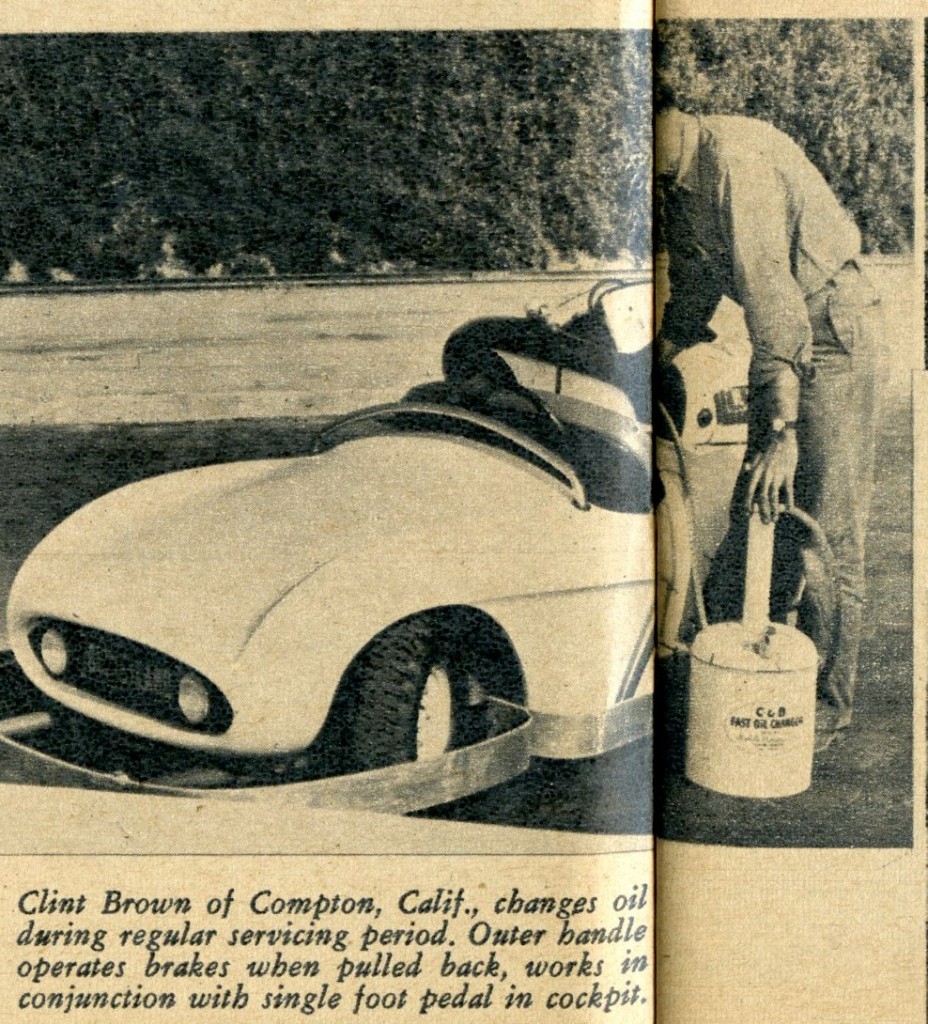

The Autopia features a ride a mile in length in a specially designed fiberglass bodied roadster. The cars feature several hot rod-type features including the use of a 7 1/2 hp cycle engine with an automatic transmission and an automatic braking system.

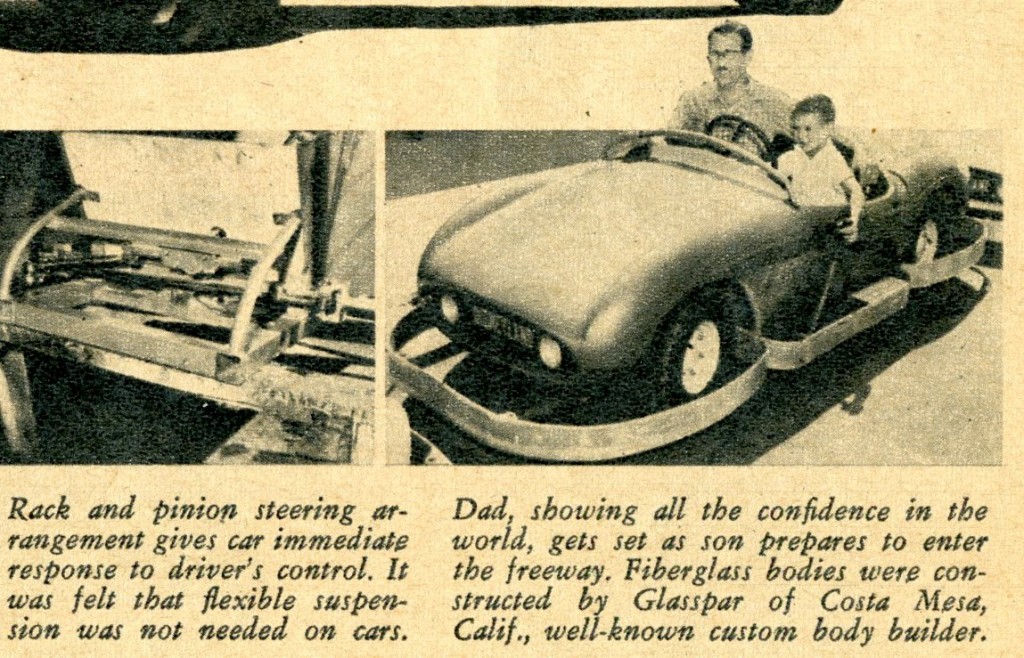

Wanting a futuristic car that would be both safe and big enough for children or a child and a parent–or two adults–Disney’s engineer called in Johnny Hartman from nearby Montrose. Johnny is no newcomer to the game as he has been responsible for several successful track roadsters, street rods and special speed equipment for the reliable old Chevy 6.

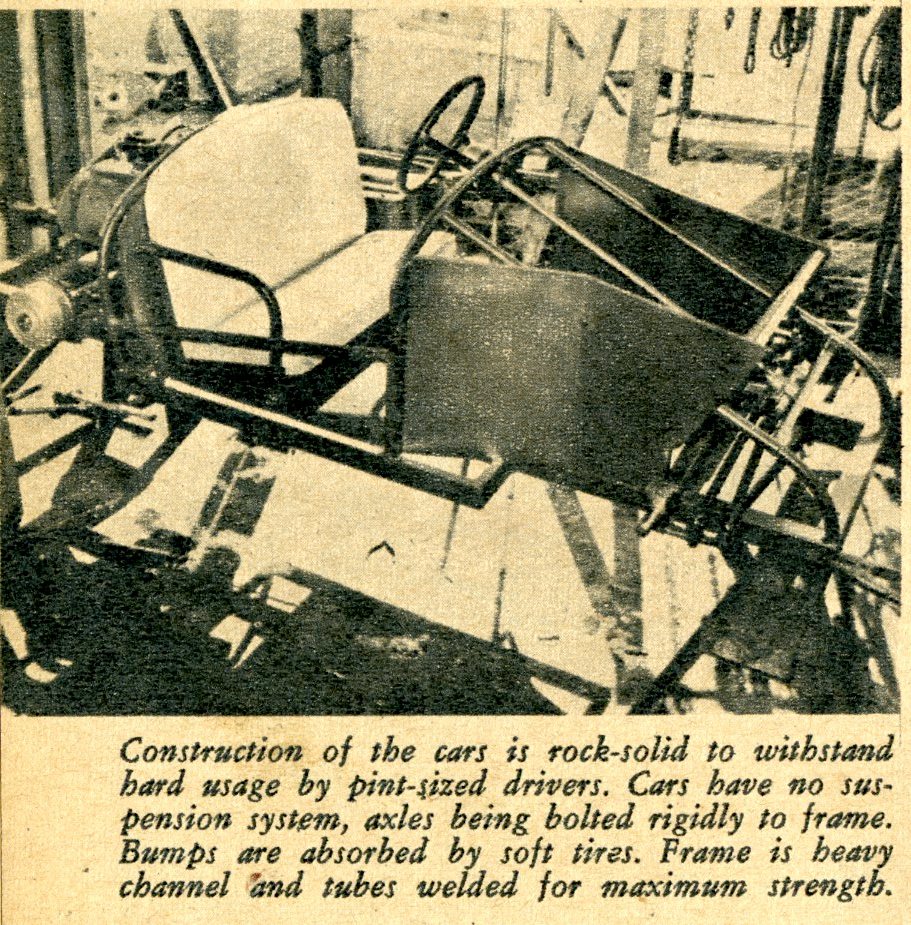

Presently occupied with orders from the aircraft industry, Johnny nevertheless took time away from his machine shop to create and develop a functional chassis sturdy enough to take the bumps and bangs that the amusement park’s kids would subject the cars to during a 12 hour day, seven days a week, 365 days a year.

When the Hartman Engineering Company completed the prototype, Robert Gurr–formerly with Ford during the designing of the forthcoming Continental–worked out the kinks associated with mass production and designed a functional-looking sports car-like body. The bodies bear a slight resemblance to the best lines of Mercedes, Maserati, Ghia, and others all rolled into one.

Added touches to the production models were wraparound aluminum bumpers, chromed hand rails on the cowl, a foam rubber covered dashboard, sealed beam headlights with a friction-driven generator to operate them and a unique automatic braking system. The latter is a revision of the Mustang cycle brake but using wider linings and with the feature of being automatically applied when pressure is lightened on either accelerator pedal or when the outside hand brake is pulled back.

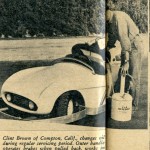

The Gurr-designed bodies were made of Fiberglass by Glasspar (the largest Fiberglass body plant in the country until Chevrolet followed suit with the Corvette), located in Coasta Mesa and the cars, 40 of them, were assembled and tested by Mameco Engineering in Newport Beach.

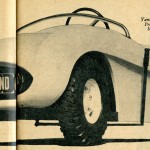

The 160 lb. frame is fabricated from 2″ square cast iron tubing and 1″ pipe. The metal body supports are made from 16 gauge sheet stock. The entire car weighs 475 pounds dry. The spindles are cast steel and the front axle is of 1 1/2″ square tubing. The rack and pinion steering gear assembly, comparable to the type used in expensive foreign cars, has a ratio of 7 to 1.

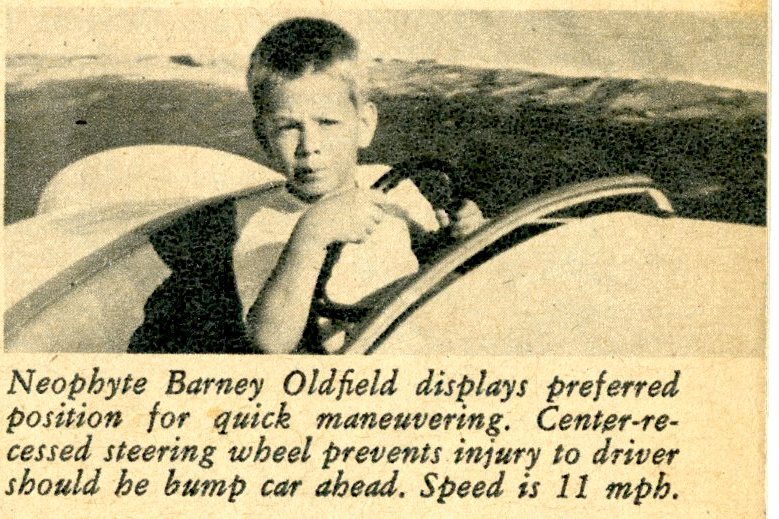

Another safety feature is the custom designed 3-spoke, rubber covered steering wheel with a recessed center to prevent injury to the drivers in case of accident–you know how freeways can be at the peak traffic hours.

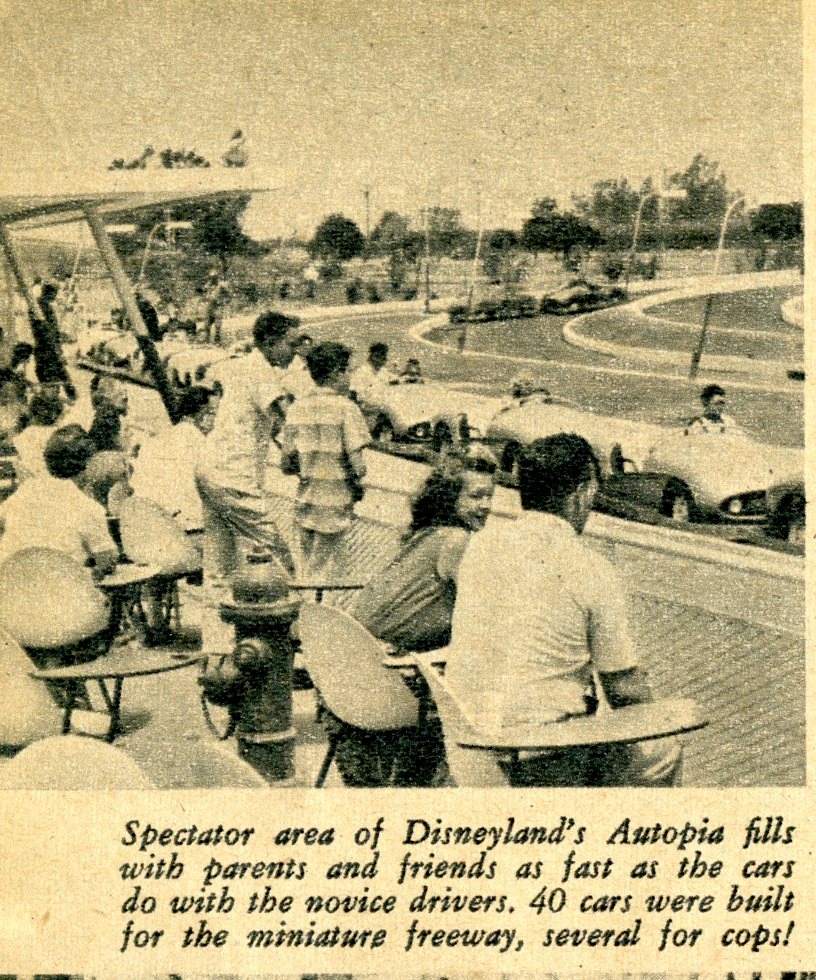

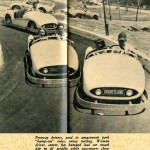

Thirty-six of the vehicles are painted in bright two-tone 1955 automobile colors, the remaining four are black and white–official colors of the California Highway Patrol. The patrol cars are equipped with sirens and red lights and other distinctive insignia.

The police cars are not governed and can attain a speed of 25 mph as compared to the conventional cars’ top speed of 11 mph. The deputies need this extra speed to enable them to unsnarl traffic jams, lend assistance to the young and sometimes bewildered rookie drivers and to sidetrack any straggling or disabled vehicles to prevent any accidents on the miniature Autobahn.

The 40 little jewels are powered by a Gladden “75”, a one cylinder mill producing 7 1/2 hp. This is the same engine used in the Mustang motorcycle and is assembled in Glendale, Calif. A Salsbury centrifugal clutch is coupled to the drive gears by means of a Gilmer belt. (Rodders will remember that this same type of belt is used to turn the blower on the Yates 435 hp Ford engine.)

Rear axles are solid and are mounted on pillow blocks. Differential gear ratio chosen for use on the ups and downs of the freeway is 16.5 to 1. Gar-Bro industrial wheels, on which are mounted 5.00 x 8.00 tires, give the little cars a soft ride over the paved mile of Autopia. A Huth Glass pack muffler is used to silence the sound emitted from the powerful little engine.

Bench type seats with foam rubber cushioning are upholstered in top grade Naugahyde to withstand the hard usage foreseen by the designers.

One of the amazing features of the miniature speedway machines was the roominess of the interior. Although the car’s wheelbase measures only 64″ with a tread of 34 1/2″, the distance from the seat forward to the firewall is fully 42″ and your 6-foot, 250 lb. road tester found it easier to get in and out of the Disney Dream car than an MG or many foreign sports models.

Controls are kept at a minimum and are simplicity itself. In the driver’s compartment you will find only two pedals–both accelerators. One is placed close to the seat within easy reach of the short legs and eager toes of the neophyte Barney Oldsfields.

The other throttle is at a more conventional distance from the seat for the adult pilots. When pressure is released or lightened on either throttle or the outside hand lever, the rear wheel brakes are automatically applied. The outer lever is so positioned to allow the operators of the concession or the roving policemen to assist in bringing the vehicles to a quick, safe stop should the need arise.

To the amazement of everyone except the far-sighted Walt Disney, these miniature hot rods are providing the biggest thrills available in Disneyland to both the young and old and the Autopia concession is proving to be the most popular attraction of the world’s largest and newest amusement park.

Summary:

How ‘bout those “police cars” on the original track! What fun that must have been to be one of the original “officers” patrolling Autopia and helping out. I wonder how long this track and car configuration lasted before significant changes were made. I bet one of the “Disney fans” out there can help us out 🙂 In the meantime, click on the link below to learn more about Disneyland’s Autopia ride:

Disneyland’s Autopia – Fun Facts

Bob Gurr recently shared that just one of the original 40 Autopia cars has survived and this car is in the personal collection of the Disney family. Subsequent to the original design, several new styles of cars replaced the original Gurr designed sports cars, and the ride continues to be one of the favorite Disneyland attractions.

Hope you enjoyed the story, and until next time…

Glass on gang…

Geoff

——————————————————————-

Click on the Images Below to View Larger Pictures

——————————————————————-

My dad, Bob Strickland, worked for Hartman Engineering for years and I remember them having the karts around and working at Disneyland. I also remember that they made the mechanics for the witches apple on the Snow White ride! It’s gone now but I was always so proud of that! My dad got to meet Fess Parker and I was a big Davy Crockett fan so I thought that was the best thing ever! FUN NOTE: My husband, who is younger than me, met Fess Parker as DANIEL BOONE at 20th Century Fox “Ranch” as a kid!

John Hartman built go karts that were second to none. I raced his karts from 1978 to 1989 on the WKA enduro circut. They were custom built to your body measurements, & came ready to race. They were a little more money, but well worth the investment. I did not know that he worked on the Disney project. I’m sure that the Disney cars were built just as well, & held up to many different drivers. WS

Quote:

Mel Keys

Posted March 4, 2012 at 9:03 PM

I wonder if anyone ever blew that up to full size.??

==================================================================

Well, the front end looks very much like the Troutman-Barnes Special sports racer driven by Chuck Daigh !

Of note… on display at the attraction was a metallic burgandy example (minus the safety bumpers). As a 10 year-old southern California enthusiast, the car made an impression on me that was to last to this day, and the inspiration of many childhood dreams. Driving this pint-sized 750 Monza to grade school was a common theme.

I think this was a “D” ticket ride, the car I drove was aqua.

Rodney

I wonder if anyone ever blew that up to full size.??

Mel

The air cleaner looks identical to those used on postwar Crosley.

I think I drove one of those on a much shorter track in 1962.

Hartman Engineering made a number of innovative engine and chassis parts for go karts after this launch. I doubt the chassis was fabricated from “cast iron pipe”, but I suppose it was available and inexpensive, so a possibility. A few years later than this, we (Go Power Corp) supplied small pneumatic wheels for “Small World” and “Log Rides” at Disneyland and other parks. Good people to work with, and very concerned with not only safety but durability. An out of service unit was not earning smiles from kids nor money for the company!

My first “sports car” experience at age 10 when we visited Disneyland in 1957. A year later I was driving my grandmother’s ’58 Buick Century and put it into a ditch as it did not handle as well as those fiberglass California cars.