————–

Note: This is the first in a series of articles here at Forgotten Fiberglass that showcase a story called “The Glassmakers 1960” published in Sportscar Graphic in May-June 1960. In this article, Almquist, Devin, Kellison, LaDawri, and Victress were showcased. We have separated the full article into the more readable “five” stories – one for each of the car marques discussed.

Click here to review all articles published in this series.

————–

Hi Gang…

If only we had an article in 1960 that told us what fiberglass companies were in business and going strong…..

Wait! We do! This 12 page tome appeared in Sportscar Graphic in June 1960 and included two pages or more on each of the following cars: Devin, Kellison, LaDawri, Victress, and Almquist. And those were the “Big Fiber Guns” of fiberglass then, and it’s a very respectful review of each of these companies and what they had to offer.

I’m going to break this up into 5 separate articles with each one focusing on a specific fiberglass sports car company from this article. Today’s story, the first in the series, will cover the introduction of this article as well as the first company: Devin.

The introduction of this article, below, is fascinating to read. It was written about 10 years after fiberglass cars were introduced at the November 1951 Petersen Motorama, and it speaks to the strides in the maturity of the business in terms of the understanding, manufacture, and building of fiberglass sports car from scratch. Ten years made a world of difference to these companies and the people who bought their bodies and built these cars.

So sit back, grab a coffee, turn on some music, and let the fibers fly free…

Off we go gang!

The Glassmakers…1960: Devin

Sportscar Graphic, May-June 1960

By Bob Rolofson

Photos by Rolofson, Bob D’Olivo and the Inman Co.

Want A Sportscar? Have Budget Problems? These Fiberglass Companies Have Economy-Minded Answers That Range From Bodies Fresh From The Mold To Completed Cars Ready For The Street Or Race Course

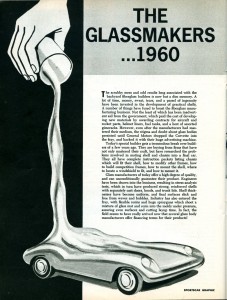

The scrubby mess and odd results long associated with the backyard fiberglass builders is now but a dim memory. A lot of time, money, sweat, tears, and a passel of ingenuity have been invested in the development of practical shells. A number of things have fused to boost the fiberglass manufacturing business.

Not the least of which has been inadvertent aid from the government, which paid the cost of developing new materials by awarding contracts for aircraft and rocket parts, helmet liners, fuel tanks, and a host of assorted gimcracks.

However, even after the manufacturers had mastered their medium, the stigma and doubt about glass bodies persisted until General Motors dropped the Corvette into the fray, and backed it with their huge advertising machine.

Today’s special builder gets a tremendous break over builders of a few years ago. They are buying from firms that have not only mastered their craft, but have researched the problems involved in mating shell and chassis into a final car.

Today’s special builder gets a tremendous break over builders of a few years ago. They are buying from firms that have not only mastered their craft, but have researched the problems involved in mating shell and chassis into a final car.

They all have complete instruction packets listing chassis which will fit their shell, how to modify other frames, how to build competition frames, how to mount the shell, where to locate a windshield to fit, and how to mount it.

Glass manufacturers of today offer a high degree of quality, and can unconditionally guarantee their product. Engineers have been drawn into the business, resulting in stress analysis tests, which in turn have produced strong, reinforced shells with separately cast doors, hoods, and trunk lids.

Shell thicknesses have become uniform, and final surfaces slick and free from waves and bubbles. Industry has also entered the fray, with flexible resins and huge spray guns which shoot a mixture of glass mat and resin into the molds under pressure, assuring even surfaces and cutting layup time. In fact, the field seems to have really arrived now that several glass body manufacturers offer financing terms for their products!

Devin:

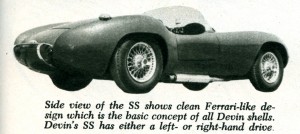

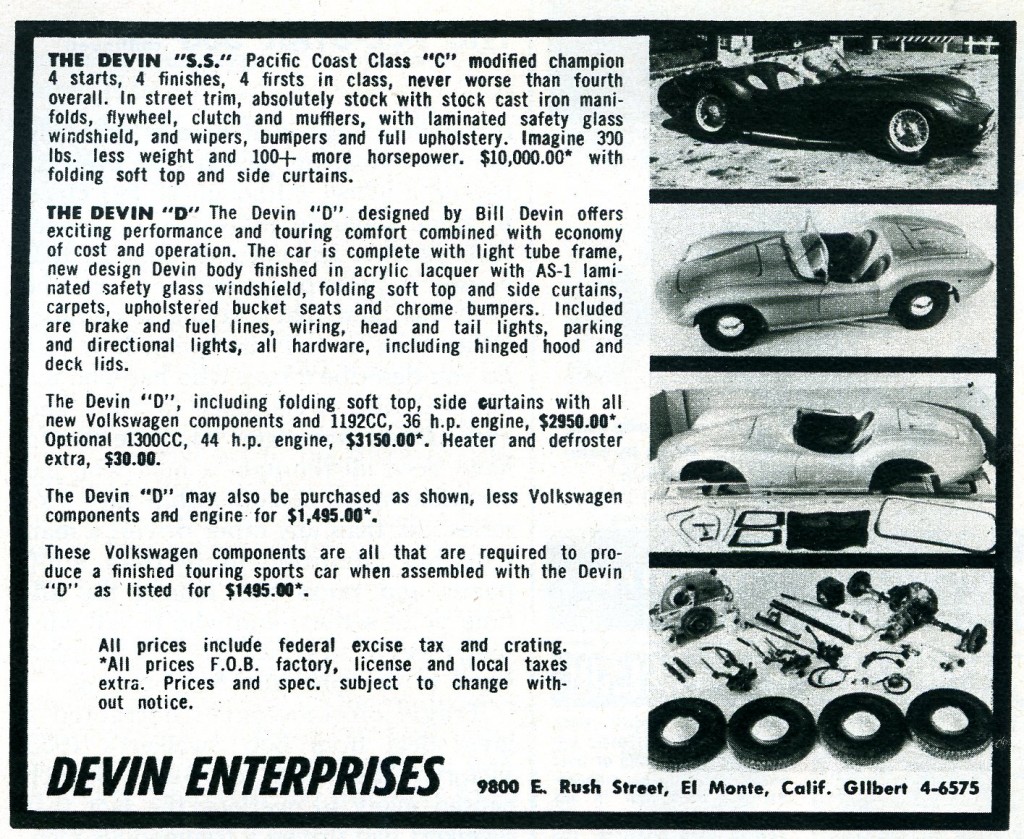

Devin Enterprises, 9800 E. Rush St., El Monte, Calif., one of the oldest of today’s glass body manufacturers, continues to cater exclusively to special builders. Priced at $295, their line runs the gamut in sizes, with 27 shells to fit almost any existing or dream chassis.

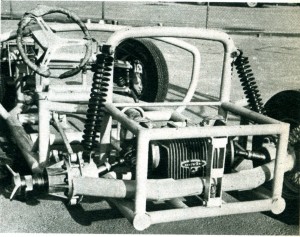

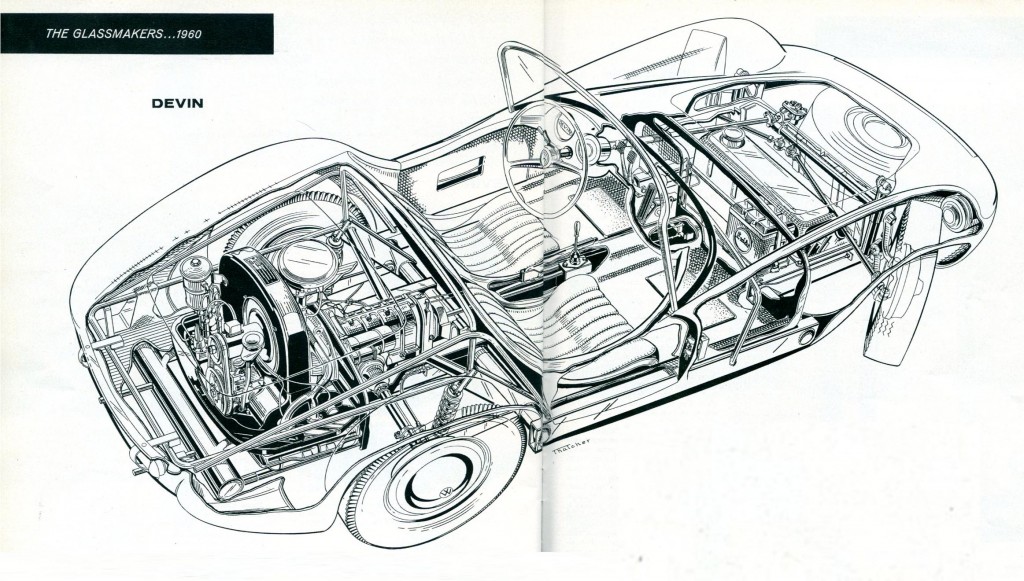

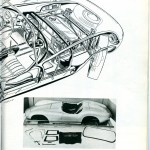

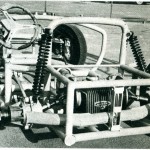

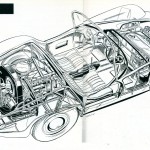

In addition to this line of commercial shells, Devin also markets the Devin SS, one of the most potent ready-built specials in the world. This Corvette-powered machine has an Irish-built Devin-designed Lister-type tubular chassis with parallel, equal-length wishbones and Woodhead-Monroe spring shocks at the front, and a full de Dion suspension at the rear.

Twelve-inch Girling disc brakes are located at the wheels in front, and 11-inch units straddle the Salisbury center section at the rear. It comes complete with hand-rubbed finish, upholstery, leather-covered bucket seats and an Italian racing steering wheel.

Twelve-inch Girling disc brakes are located at the wheels in front, and 11-inch units straddle the Salisbury center section at the rear. It comes complete with hand-rubbed finish, upholstery, leather-covered bucket seats and an Italian racing steering wheel.

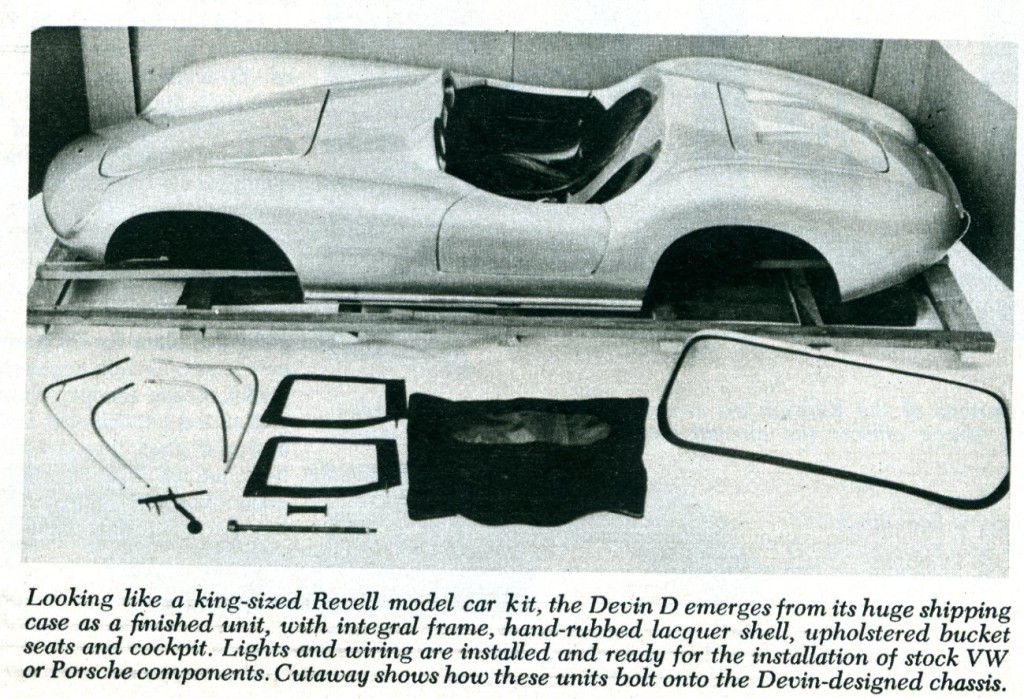

The newest addition to the line, and “baby” of the shop, is the Devin D, a revolutionary “kit car” conception.

Unlike kits of the past, the D model is complete with laminated safety glass windshield, folding soft top, side curtains, a hand-rubbed lacquer body, upholstery, leather-covered bucket seats, chrome bumpers, brake and fuel lines, all wiring, head and tail lights, parking and directional lights, and a built-in heavy-duty frame.

It arrives in a huge shipping carton ready for the installation of stock Volkswagen or Porsche components. These stock units bolt on, with no welding, drilling, or cutting necessary. In this kit form the D model is priced at $1495. If purchased as a complete car, with new VW engine and running gear, the car is tagged at $2950.

In addition to their cars and shells, Devin Enterprises markets a full line of instruments from starter switches to 200-mph speedometers, Borrani wheels, knock-off adaptor hubs, BID high-rpm clutch plates, aluminum quick release filler caps, Italian competition steering wheels, disc brakes, Devin de Dion rear end kits, and the new Devin universal intake manifold for Chevy V8 engines.

This unit permits the builder to use any carburetor or combinations of two- or four-barrel carburetors, provides added hood clearance, and easier super-charger installation.

Summary:

Bill Devin had started with his newest body shell in 1956, the one shown here in this story, and 4 years later he was up and running and growing strong with 27 different sized bodies offered for sale. His Devin SS sports car was available too – a powerful sports car by any measure.

It’s interesting to see the accessories that Devin offered to complete the car – even a Devin de Dion rear end and Devin-branded intake manifold. Impressive in every way.

Our next story from this article will focus on the Kellison sports cars from Jim Kellison, so be on the lookout for the next article in this series in the near future.

Hope you enjoyed the story, and until next time…

Glass on gang…

Geoff

——————————————————————-

Click on the Images Below to View Larger Pictures

——————————————————————-

- This Devin Ad Also Appeared In The Same Issue As The Article Above in June, 1960.

Great story Geoff..I know a little bit about mould making,but I cant figure out how in the world Devin could make them adjustable.I would like to see how it was done.

Mel

Great piece on Devin cars! For those looking for further reading on the topic, I recommend the book “Devin The Man and his Cars” by Art Evans:

http://www.amazon.com/Devin-Man-his-Cars-Evans/dp/097972192X

Devin made all their molds adjustable for different widths and wheelbases. Pretty slick idea for the time and still today.