Hi Gang…

I’m sure that Doc Boyce-Smith, founder of the Boyce-Smith Company which produced the Victress S1 sports car body in ’52 and ’53, felt like Paul Revere when a car using the Victress body set the record for “Fastest Sportscar In The World” at Bonneville in ’53. I’m sure he shouted…

“Victress….Worlds Fastest Sports Car! Victress….Worlds Fastest Sports Car!”

And who wouldn’t? The company he founded in late ’52 had achieved fame and notoriety in such a short period of time. And just after the Bonneville record his car was selected as one of the feature cars of the upcoming movie “Johnny Dark” staring Tony Curtis and Piper Laurie.

I can’t imagine how excited he and the folks at Victress were back then. And here it was in August 1955, Motor Life was not only reporting on the achievement from two years ago, but featuring the “World’s Fastest Sports Car” again in its latest form – poised to continue its success in a newly modified form.

Let’s see what Motor Life had to say about the second life of the Guy Maybee Victress – the World’s Fastest Sports Car.

The World’s Fastest Sports Car

Motor Life, August 1955

By John Christy

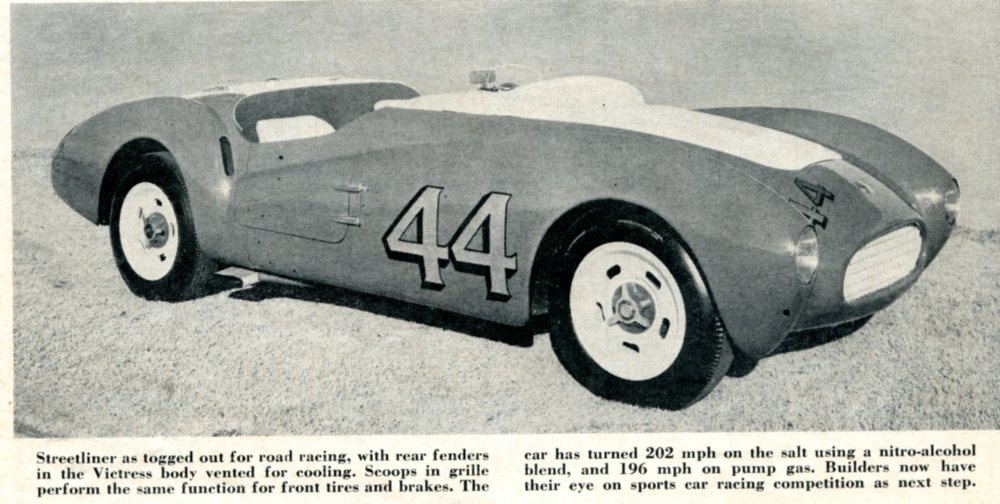

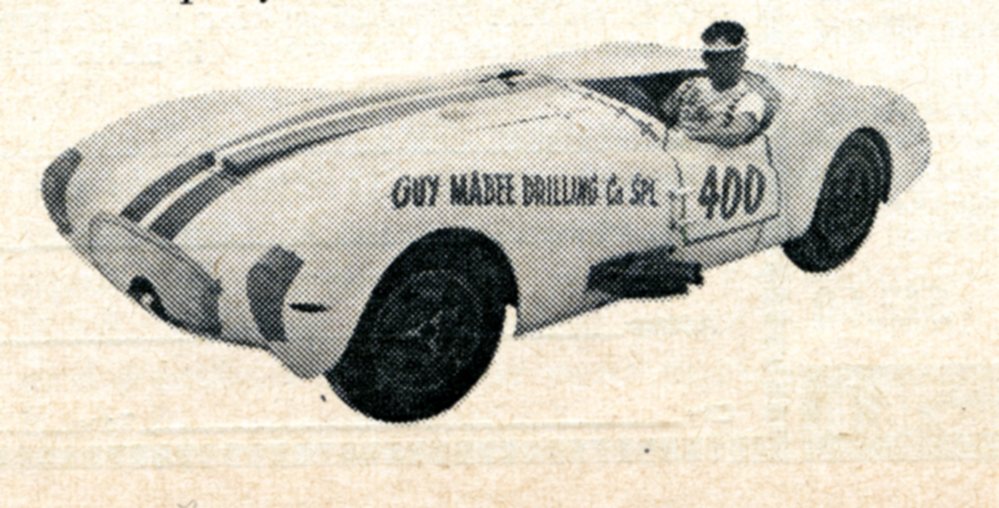

The Mabee Special is a piece of backyard machinery known variously as the “Streetliner” and as the “Fastest Sports Car in the World.” Both terms had been used two years ago when the car turned 202 mph at the Bonneville trials. At the time there was some justification for calling it a Streetliner, since the car never would have passed the road race technical committee.

The following year the car was changed from alcohol-nitro to gas and ran a top time of 196.50 mph. So the owners, Texas oilman Guy Mabee and his son, took the car to the March Field sports car road races. After a fast start the car was in and out of the pits, but hung to within a lap of the leaders and finished seventh.

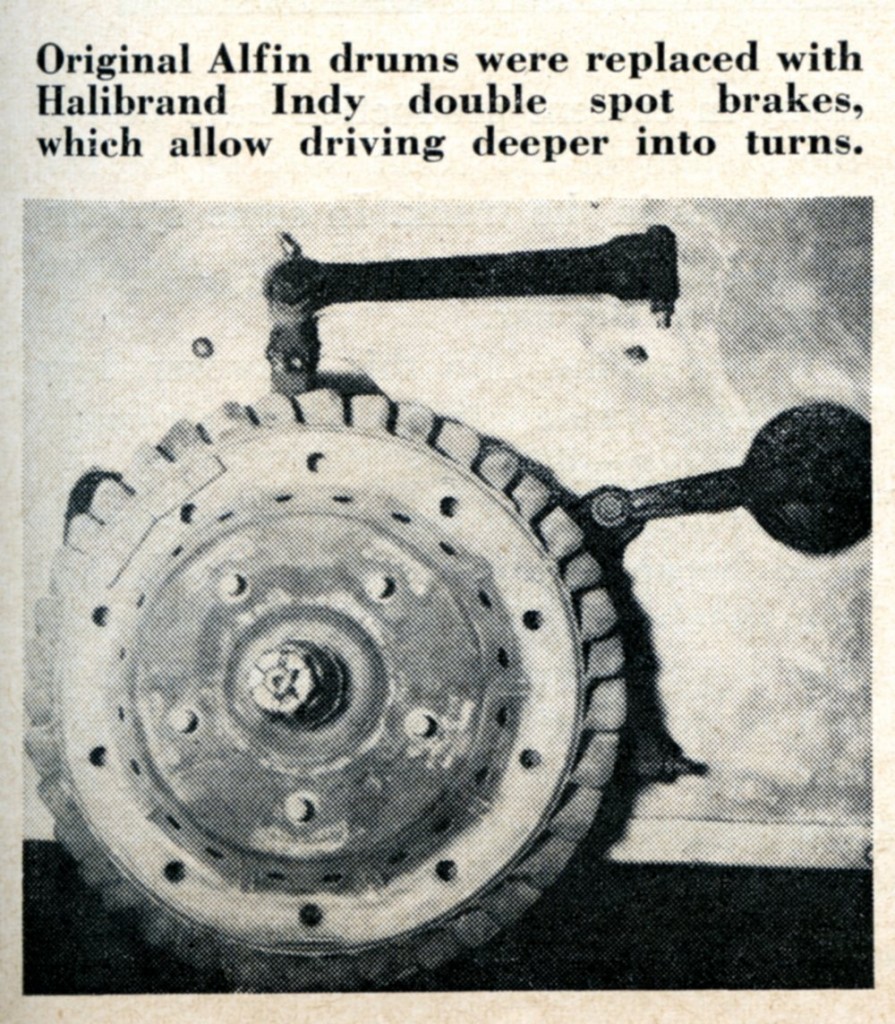

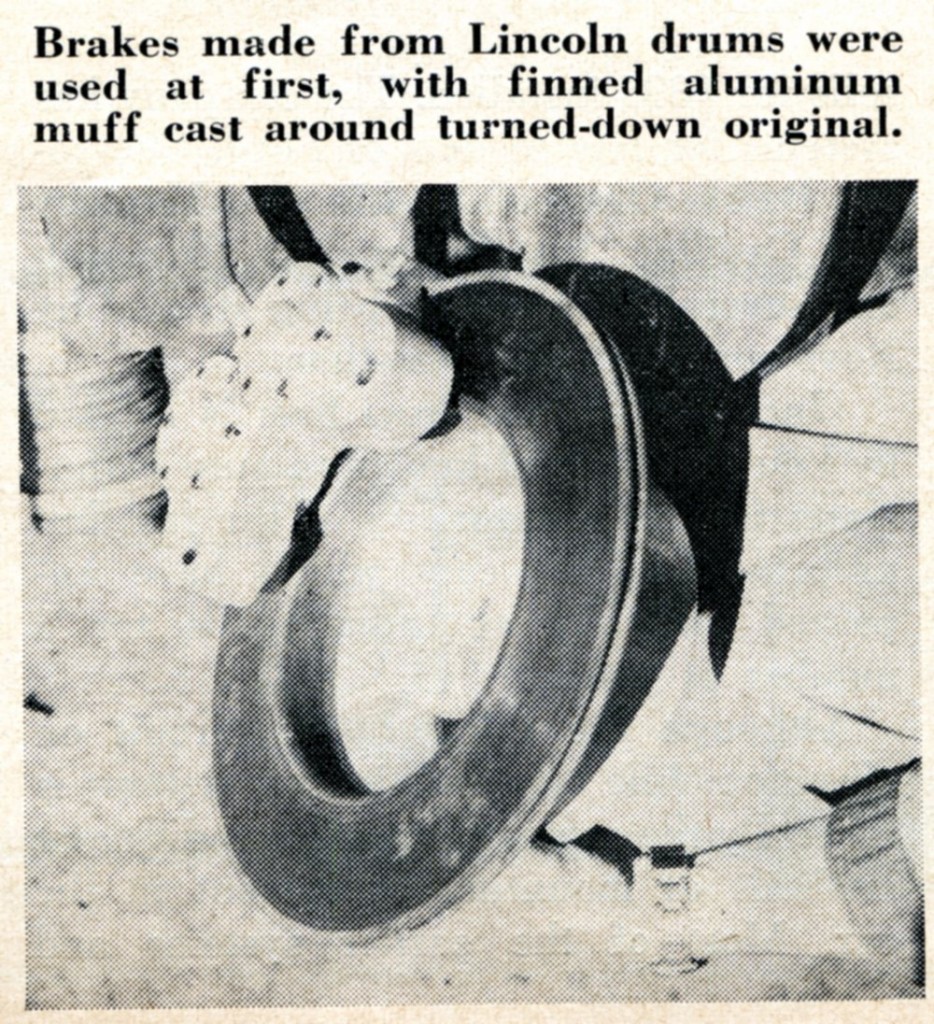

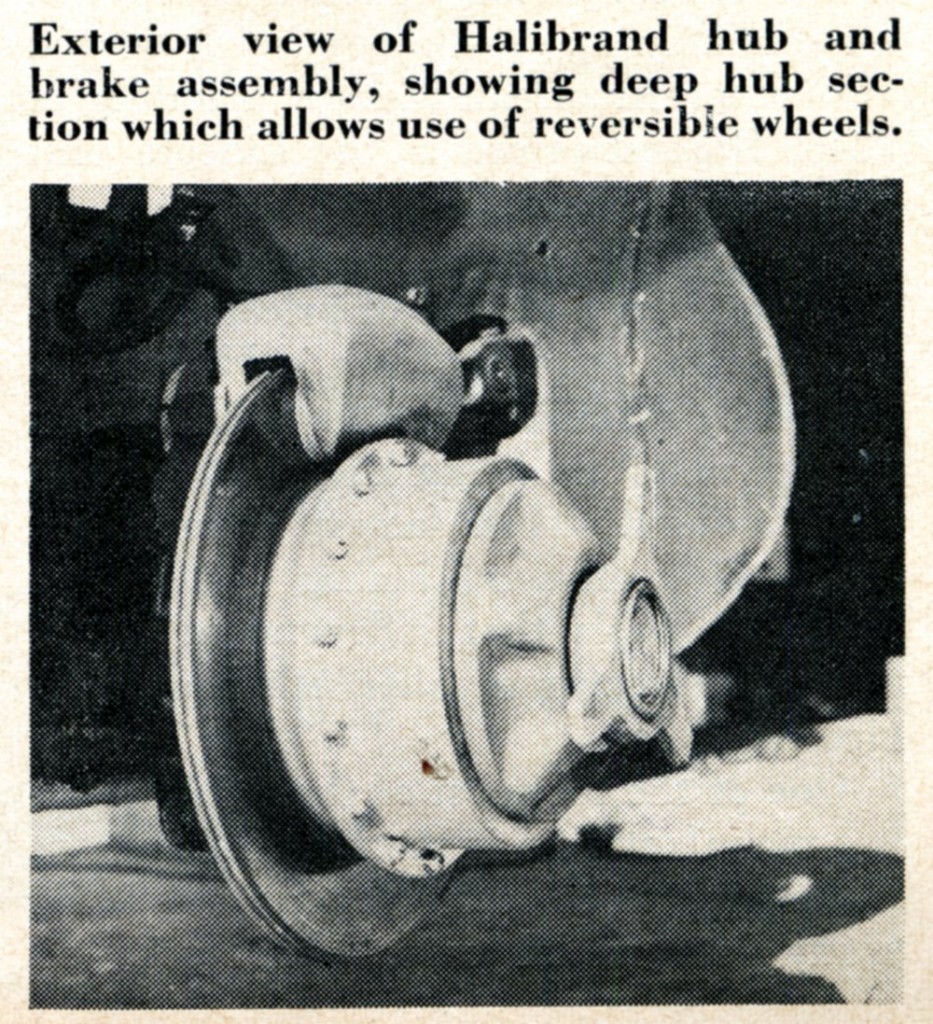

Originally, the streetliner chassis was a double rail affair, following Chuck Manning’s principle of close-set truss tubing but with heavier two-inch chromemoly tubing and set up for transversely placed torsion bars instead of leaf springs. Front and rear axles were 1946-48 Ford, the rear equipped with a Halibrand quick-change center section. Brakes on all four wheels were reworked 11-inch Lincoln units modified by Chuck Manning into his version of Al-Fins. Kurtis torsion bars were used all the way around. Wheels were and are Halibrand pin-drive knock-off disc units.

Since its maiden trip to the salt, several changes have been made. The front end has been modified to take the Kurtis tubular axle and the steering has been rerouted so that the column now passes under the left rocker cover on the engine rather than over it as originally built. The same Gemmer sector is used with a Kurtis pitman arm. The homemade brakes have been discarded in favor of Halibrand double-spot brakes and Indianapolis reversible wheels can replace the sports car type shown here.

A 389 cubic inch (6.37 litre) Chrysler V-8, modified by Ray Brown Automotive, produces 350 hp on gas at 5100 rpm. To achieve this healthy performance, the engine has been bored three-sixteenths oversize to four inches and stroked .250 of an inch to give a piston travel of 3 7/8 inches. To stroke a Chrysler crank that much requires that each crankpin be metal sprayed to bring it back to size. The metallurgy of the crank is such that the collar formed by the spray breaks loose under stress and twists on the crankpin. Brown solved this problem by setting bronze pins 180 degrees apart in each journal. The throws were then ground to size and no shifting of the new metal has been noted after a year of hard use.

Another problem lay in the fact that at high speeds the drive gear on the cam and the driven gear carrying the magneto shaft would wear at racing speeds to such an extent that as much as 10 degrees of slop would be noted in the ignition timing. Experiments showed that these gears were not getting sufficient oil to keep the steel drive gear from chewing up the cast iron magneto drive.

A study of the oil passages showed that two galleries ran through the block alongside the tappet bores. Each bore had a hole leading to these galleries to provide pressure to the hydraulic tappets but since roller tappets were used in the modified engine, these were found not only unnecessary but detrimental. The 80-lb. oil pressure actually caused side thrust and resultant wear on the tappets.

The holes were plugged with brass rod, thus letting full pressure go through the galleries around to a plug at the left rear, leading into the magneto drive chamber. This plug was drilled with a .030-inch hole and the wear problem was stopped due to the resulting stream of oil which bathed the two gears. It’s the little things that count.

The heads were modified by cleaning out the ports and enlarging the intake valves to 2 1/16 inches. Sodium cooled valves were then set into big-bore bronze guides. Chrysler Marine rockers, which are adjustable, replace the stock items and are used with very light .058 wall chrome-moly push rods manufactured by Brown’s company.

The stiffness of these push rods is such that there is less than .010 of an inch whip with the engine operating at 5000 rpm! No milling was done to the heads, the increase in displacement, coupled with the use of J.E. high dome racing pistons being sufficient to bring the compression up to 10-to-1.

Induction for record runs is by the injector system. On shorter road courses a triple carburetor manifold bearing three Stromberg dual throat carburetors is used. Experiments are now being made to set up the injectors for full-time use, however.

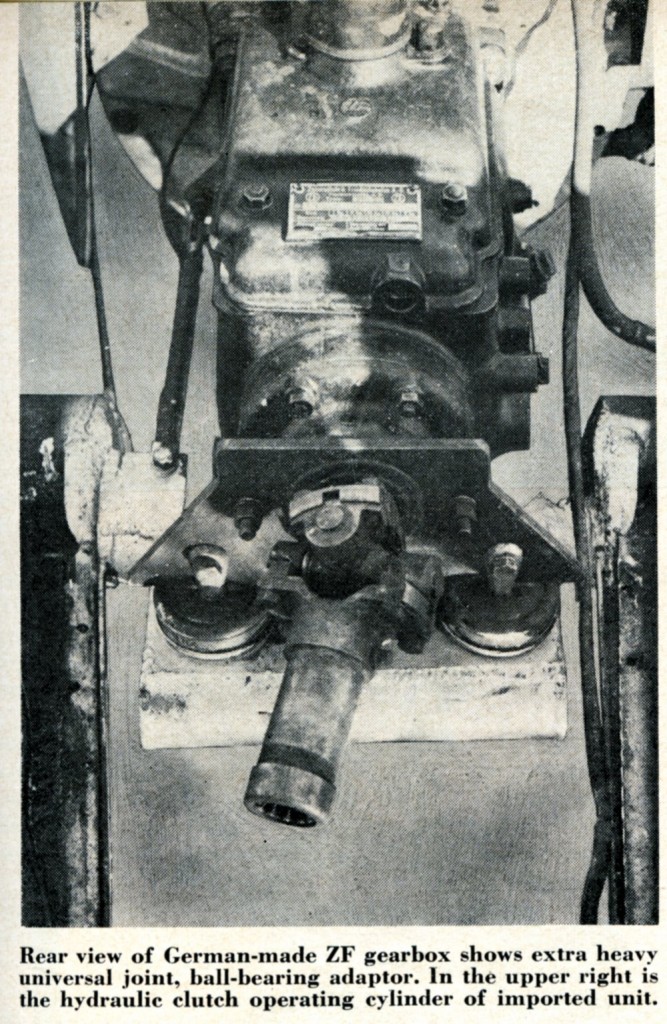

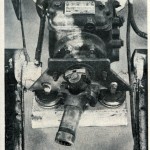

All this pressure is delivered to the driveline via a stock flywheel and a 2800-pound Frictionmaster clutch to a ZF four-speed gearbox and thence to the shortened late Ford drive shaft.

The German made ZF (Zahnradfabrik Friedrichshafen, A.G.) box was a later addition, installed when it was found that the Ford transmission, while sufficient for straightaway runs, was not beefy enough nor of close enough ratios for closed circuit road racing. Although expensive and not easy to acquire, the ZF box has for years been practically S.O.P. in Grand Prix due to its ruggedness and even ratios of 25 percent step-up between gears.

All of this proves a point,that point being that a successful sports car does not have to have the tradition of years behind it to be good but it does have to have considerable thought and cooperation in its design and make-up.

Summary:

And the Guy Mabee Victress survives to this day – too fast and too important to have disappeared in the mists of time. Owners Jim and Lea Ann Robinson most recently featured their Victress at the Milwaukee Masterpiece Concours d’ Elegance. Click here to review this special showing in Milwaukee in 2011.

And rumor has it that their Victress may appear at the Salisbury Concours d’ Elegance later this year held in Des Moines, Iowa. So if you want to see their car again, be sure to post your comments at the bottom of this story and let ’em know how you feel. How great would it be to see this special car again this year 🙂

Hope you enjoyed the story, and until next time…

Glass on gang…

Geoff

——————————————————————-

Click on the Images Below to View Larger Pictures

——————————————————————-

Although this article calls the original brakes “Al-Fins” I think these were actually copper finned brakes that were designed by Chuck Manning but made by Dave Margolien. Chuck and Dave went into business together called Copper-Flow. I am still learning about this company and hope to post a story about it on this site.

I also find it interesting that they used Chuck’s idea of a close truss frame but, they went against what Chuck preached, you don’t need Chrome Molly tubing for the frame. But then again this isn’t like Chucks car which was made for a supposed $700, this one looks like cost wasn’t a player in what they got, thus paying for the chrome molly.

Quite a car! You may want to look into a Kelmark GT that topped out at 205 MPH on a closed track in Ohio, some years ago. It is also fiberglass kit car.

The ZF transmission shown here was originally built for mid-size trucks. Years ago John Bond told of them in one of his Sportscar Design articles. He stated that Briggs Cunningham purchased 6 with aluminum cases. These were for the C6R offy powered Cunningham. Also in 1956 one of the Corvettes at Daytona Speed Week had a cast iron one like this car had. [Corvette had no 4-speed until 1957]

I have one of these ‘beasts’ that came with and adapter to a 331 Cadillac belhousing. I have yet to find what it was originally in.

It took years of research to piece most of the ZF’s history togeather on them. The ZF offices in Germany and London had no records of it. A couple of years ago I saw some parts for one on a Dutch car site. The guy was from one of the former ‘Iron Curtain’ countries and was a vintage truck collector. It is odd what the inter-net comes up with at times.