Hi Gang…

Last month we published part 1 of this series – an article by Robert Cumberford that appeared in Car and Driver Magazine in September, 1962. Click here to review part 1 of this series. In that article, Cumberford reviewed his experience and thoughts on designing and building your own fiberglass body and the effort it took to do so.

He ended his article back in 1962 with this sage advice for those strong-willed folks who wanted to design and build their own sports car body:

“If you have a passionate longing for a body made of fiberglass, buy one ready-made. There are at least 30 types to choose from, and you ought to be able to find something you like among them. If, on the other hand, you are more interested in having a body built to your own designs than in the material it’s made from, don’t make it yourself-hire Pininfarina or Vignale or Ghia or Fantuzzi. Anyone of them will build a superbly finished, trimmed and painted body on your chassis cheaper than you can in fiberglass-and far better than you can hope to.” Robert Cumberford, Car and Driver: September 1962.

Is that the end of the story? I’m pleased to say “no.” I’m honored to have been corresponding with Robert for the past few years and asked him if he would take the time to review his earlier article and share his thoughts on how the article has held up over time – now over 50 years old.

I’m pleased to say that he agreed to do so, and it’s with great thanks and appreciation that I share with you, today, Robert’s thoughts on the his original article titled “Don’t Build That Fiberglass Body!”

With that said, take it away Robert 🙂

Robert Cumberford

Reaction to Article From Car and Driver Magazine: September 1962

Thanks to the diligence of Geoff Hacker, I recently had a chance to re-read a Car and Driver article I wrote almost fifty years ago with the provocative title “Don’t Build That Fiberglass Body.” It’s an article I wish I’d read about fifty-two years ago, before I built my first fiberglass body.

It probably wouldn’t have discouraged the energetic young guy I was then, but it should have done so. As I told Geoff in an e-mail, I stand behind every word written so long ago. Making a one-off fiberglass body is a thankless task, best left to skilled professionals.

Oh, I’ve succumbed to the lure a number of times in the intervening years, but looking back, I honestly wish I hadn’t. The design part is easy, particularly for me, as I am a professional designer, but once I’d done a scale model, I should have stopped all physical effort and left it to someone else.

I did that for a radical CanAm race car just four years after writing that article. I made a clay quarter-scale half-model, did full-size drawings and turned the whole job over to my client’s crew. And to my surprise, the two or three racing mechanics, a machinist and a carpenter shop boss did an absolutely splendid job of making a full-size buck in a matter of a couple of weeks.

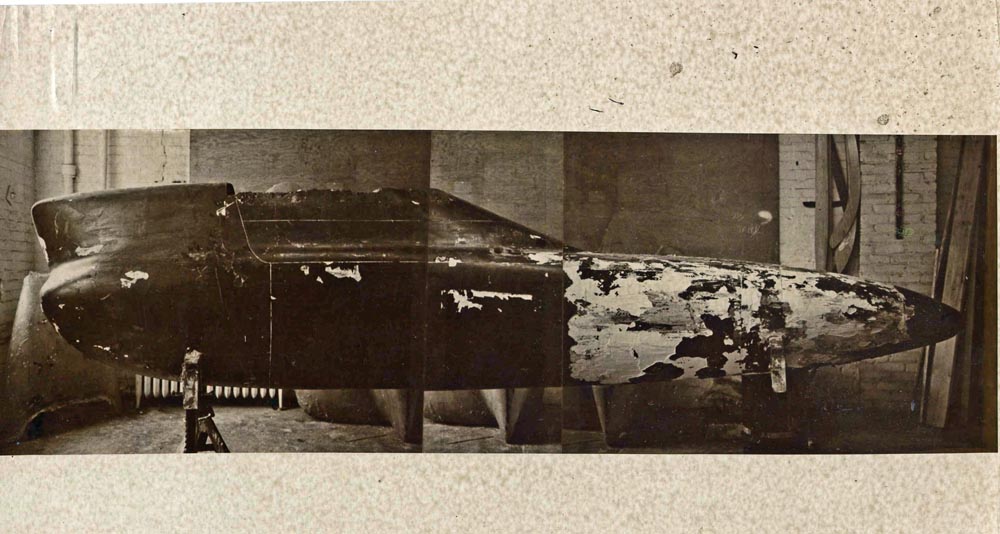

From Robert Cumberford: “Geoff, In searching for a good picture of the ’59 Formula Junior, I came across this shot of the Can Am body plug mentioned in my introduction, done by my client’s team that had never done anything like it before. This was hand-cut from urethane foam, then primed and sanded. Best, Robert”

They had never done anything like it before, but armed with really accurate drawings and photos of the model, they accomplished the task perfectly. If I had done it myself, as I had on a Formula Junior car, my first solo effort, it would have taken me months, despite my knowing what to do and how to do it. For someone without the same car design experience, the time would probably have been measured in years.

From Robert Cumberford: Geoff, In 1959, on the 5th floor of a garage on the upper East side in Manhattan, I built the body for a Formula Junior. Pretty radical, first-ever layback driving position as far as I know. Front engine, using the British Ford 105E 80mm bore 1 liter engine. Project got bogged down for lack of finance, finally shipped the molds to Bill Devin. Don’t know what he did with them, but I’d sure like to have a body so I could make a Junior to that design. Except, of course, that 51 years later I’d still get bogged down for lack of finance. Best, Robert.

Today no one need spend all that effort. Thanks to computers and digital data, these days we make a male model for a car body by machining it out of blocks of plastic foam — sometimes low-density material that can be cut in a single day, sometimes materials hard as oak that takes two or three days, Those shapes can be used for making molds, for checking dimensions, or even painted and finished to look like a real car in order to attract investors.

If you really, really want a one-of-a-kind car of your own design, and you really do have adequate talent to create something of which no one would be ashamed, then follow the advice in that long-ago article: don’t do it yourself, hire someone who knows how to do it for you.

The late, great amateur designer Richard Bosley, who made two exceptionally fine fiberglass bodies for one-off cars in the Fifties, told me that when it was all done, he could have had his cars made in Europe for a lot less money than he spent, in a lot less time.

I said in 1962, and I say now, older and (I hope) wiser: Don’t Build That Fiberglass Body!

Summary:

Thanks again to Robert Cumberford for taking the time to both review his earlier article and share his thoughts with us 50 years later.

Robert continues to write with great vigor and insight for Automobile Magazine, and I encourage you to pick up a current magazine and enjoy his writing as I do – each month. For those of you interested in learning more about Robert Cumberford and his history, you can click here to review a recent profile on him printed in April, 2011 by the same magazine.

Hope you enjoyed the story, and until next time…

Glass on gang…

Geoff

Pingback: URL

Robert hits another home run in practical realities. As a 12 year old reading Air Progress in the 70’s I marveled at his innovative looking concept model of a futuristic Biplane Racer with a Ford 289. Well within the rules, the air racing body quickly enacted rules to ban such innovation and forward thinking, but I know Robert was right and his designs, thoughts and good practical application molded may of my own projects through the years. Thanks Robert Cumberford!

Rodney flatters me, that my advice might have value. Geoff and others have documented the time and effort that each fiberglass body producer, one-off or limited-production (such as we at Victress) invested in developing a fiberglass automobile body. Robert’s advice is sound, from a practical standpoint. I agree, however, with Ted Parks, that if no available product meets your ideals, go for it!

Merrill

Thank you Geoff Hacker for bringing us the “Don’t build that fiberglass body” article and now the comments from Mr Cumberford. I am an official member of this demented group of guys who has decided to design and build his own car (you can see mine at VarsityRoadsters.com) and could really relate to Mr Cumberford’s comments. Why would anyone in their right mind attempt such a ridiculous project? If you think like an engineer, or a mechanic, or a scientist, you would quickly see how inefficient and impractical the job would be, and simply move on. But an artist thinks differently…An artist’s brain is rarely contaminated by thoughts of practicality, logic or even common sense. To me, these one off fiberglass cars from the 50s and 60s are masterpieces, stunning, gorgeous works of art that are as pleasurable to look at as anything one would find in a fine arts museum. After sinking 15 years and everything I own into my own project, I couldn’t agree more: Don’t Build That Fiberglass Body!!! BUT, the planet is a much more beautiful place thanks to the graceful lines, curves and contours of cars like those that Robert Cumberford and his contemporaries have designed.

~ @ Ted Parks,

you might consider yourself demented or not of right mind however i have to tell you that i consider your effort eminently successful. Mr. Cumberford may be precisely correct for 99.9% of us but it appears you were up to the challenge.

I love the period design of that CanAm Bodywork.

Was / were the car(s) ever finished ?

What was the name of the car ?

How many were built ?

Any still in existence ?

I completely agree with Robert. I built a complete fiberglass car in the early 1980’s. It took nearly 5 years. It was insanity, accomplished with a combination of youthful foolishness and sheer tenacity. Today there are so many capable teams that make wonderful cars (due in part to the extensive restoration projects undertaken on million dollar cars) that the “cost” of engaging a professional shop is well worth it.

Think of how much better an orchestra sounds with each section playing their instrument with practiced precision. Now imagine trying to run from section to section on your own, playing each part. You will might indeed finish the performance, but the finished piece might not be to the standard that a team of professionals can produce!!

I love both of the efforts illustrated in this story. My first race car was a Fornula Junior, and a very pretty one, but the lines of Mr. Cumberford’s Junior look nicer than anything of the era. I’m glad we have the option of calling Merrill Powell for advice in this realm.

How true this is. I was one of the foolish ones who tried to build a one-off fiberglass body using a home made frame, midengine chevy v8 hooked to a corvair transaxle using a Kelmark adapter. The body was awful and I should have taken the advice of buying an already in existance fiberglass body.

Robert , your design is timeless, would look great on the street or track today. Great story!